1 / 4

130tonプレスブレーキサーボ駆動型3+1軸

Nominal pressure (kN):

- 630

- 1600

- 800

| degree of automation : | Automatic |

|---|

製品説明

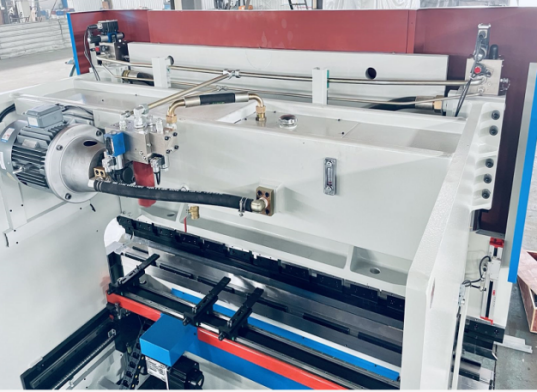

曲げマスターCNC油圧プレスブレーキWE67K-130T4000

パフォーマンスと機能:

A: High-configuration, high-precision, high-efficiency full CNC sheet metal Press Brake

B: The frame is integrally welded and heat treated. The overall machining of the boring machine has high precision and good rigidity

C: This machine adopts imported high-performance hydraulic system and internal gear pump

D: Standard 3+1 Axis, equipped with Delem DA53T System

E: Siemens main motor, Schneider Electric

オプションの構成:

A: Multi-Axis options: 4+1, 6+1, 8+1...

B: Laser guards, as well as side and rear fence protection

C: CNC System: DA58T, DA66T

D: Main Servo Motor

Frame part: This part is a frame-shaped structure, which consists of a workbench vertical plate, left and right side plates, connecting beams, and mechanical deflection compensation devices. The steel plate is welded as a whole, with good rigidity, high strength, and good resistance to distortion and deformation; internal stress is eliminated through surface shot peening and other processes to ensure the lasting stability of the overall accuracy of the machine tool; the upper slide plate and worktable are deformed during bending Small quantities ensure the work-piece has excellent straightness and angular consistency.

Upper slide part: the left and right oil cylinders are tightly connected with the frame with bolts, and the piston rod of the oil cylinder and the slider are connected with a spherical gasket and a screw rod. Combination performance with the slider; the slider and the frame are connected by a rectangular guide rail pair with self-lubricating function; magnetic scales are installed on the C-shaped plates on both sides of the frame to detect and feed back the synchronous movement state of the two oil cylinders to ensure Controls the slider travel position.

|

|

Mold and clamping device: The mold is composed of upper mold and lower mold, which is of high quality and durable. The upper die is installed on the slider and fixed by a precise quick clamping device, and the lower die adopts the double V concentric form, which is convenient and quick to change the die, reduces labor intensity and improves production efficiency.

Front support bracket for linear guide rail: This part is a standard part and is installed on the front of the worktable. When in use, the material support bracket can be manually moved to an appropriate position through the linear guide rail according to the length of the work-piece , and the material support bracket can be adjusted in the horizontal and vertical directions.

Throat deformation compensation device with special structure: a grating ruler is installed on both sides of the machine tool to measure and feedback the precise distance between the slider and the lower table. The grating ruler is connected with the worktable through the C-shaped frame, which completely eliminates the influence of the deformation of the throat of the frame on the position of the slider; the position data of the slider is fed back to the numerical control system, and the output signal of the numerical control system controls the hydraulic proportional servo valve It controls the actions of the two sets of electro-hydraulic proportional servo valves respectively, so that the two oil cylinders can keep precise synchronization. This structure can make the machine have anti-eccentric load ability, and can effectively prevent non-standard work-piece from colliding with the interference grating ruler.

Back gauge device: The latest self- design of the precise and stable back gauge device is adopted, and the servo motor drives the ball screw, which has the characteristics of high speed and high positioning accuracy; the novel and unique double linear guide structure ensures the highest positioning accuracy; more The high-grade gear design increases the positioning range, and the value for money is excellent; the modular design, the number of control axes can be selected from single-axis X, optional to multi-axis.

技術データ:

|

Parameter & Specification |

Nominal Pressure (KN) |

Worktable Length (mm) |

Distance between uprights (mm) |

Throat Depth (mm) |

Ram Stroke (mm) |

Max Opening Height

(mm)

|

Main Power (Kw) |

|

WE67K-40/2000 |

400 |

2000 |

1700 |

200 |

120 |

390 |

4 |

|

WE67K-63/2500 |

630 |

2500 |

2000 |

250 |

150 |

420 |

5.5 |

|

WE67K-100/2500 |

1000 |

2500 |

2700 |

400 |

200 |

470 |

7.5 |

|

WE67K-100/3200 |

3200 |

3300 |

|||||

|

WE67K-160/3200 |

1600 |

3200 |

2700 |

400 |

200 |

470 |

11 |

|

WE67K-160/4000 |

4000 |

3300 |

|||||

|

WE67K-200/3200 |

2000 |

3200 |

2700 |

400 |

200 |

470 |

15 |

|

WE67K-200/4000 |

4000 |

3300 |

|||||

|

WE67K-250/3200 |

2500 |

3200 |

2700 |

400 |

250 |

520 |

18.5 |

|

WE67K-250/4000 |

4000 |

3300 |

|||||

|

WE67K-250/5000 |

5000 |

4300 |

|||||

|

WE67K-300/3200 |

3000 |

3200 |

2600 |

400 |

250 |

520 |

22 |

|

WE67K-300/4000 |

4000 |

3300 |

|||||

|

WE67K-300/5000 |

5000 |

4000 |

|||||

|

WE67K-300/6000 |

6000 |

4800 |

|||||

|

WE67K-400/4000 |

4000 |

4000 |

3300 |

400 |

320 |

630 |

30 |

|

WE67K-400/5000 |

5000 |

3920 |

|||||

|

WE67K-400/6000 |

6000 |

4720 |

|||||

|

WE67K-400/7000 |

7000 |

5020 |

|||||

|

WE67K-500/4000 |

5000 |

4000 |

3000 |

400 |

350 |

650 |

37 |

|

WE67K-500/5000 |

5000 |

3800 |

|||||

|

WE67K-500/6000 |

6000 |

4600 |

|||||

|

WE67K-500/7000 |

7000 |

5600 |

|||||

|

WE67K-600/5000 |

6000 |

5000 |

3900 |

500 |

320 |

650 |

55 |

|

WE67K-600/6000 |

6000 |

4800 |

|||||

|

WE67K-600/7000 |

7000 |

5400 |

|||||

|

WE67K-600/8000 |

8000 |

6000 |

|||||

|

WE67K-800/6000 |

8000 |

6000 |

4800 |

600 |

400 |

920 |

55 |

|

WE67K-800/7000 |

7000 |

5100 |

|||||

|

WE67K-800/8000 |

8000 |

6100 |

|||||

|

WE67K-800/10000 |

10000 |

7800 |

|||||

|

WE67K-1000/6000 |

10000 |

6000 |

4800 |

600 |

400 |

920 |

37X2 |

|

WE67K-1000/7000 |

7000 |

5100 |

|||||

|

WE67K-1000/8000 |

8000 |

6100 |

|||||

|

WE67K-1000/10000 |

10000 |

7800 |

|||||

|

WE67K-1200/6000 |

12000 |

6000 |

4800 |

600 |

400 |

920 |

45X2 |

|

WE67K-1200/7000 |

7000 |

5100 |

|||||

|

WE67K-1200/8000 |

8000 |

6100 |

|||||

|

WE67K-1200/10000 |

10000 |

7800 |

NANTONG XINTONGWEI MACHINE TOOL CO.,LTDもっと見る

このサプライヤーにお問い合わせを送ってください