1 / 2

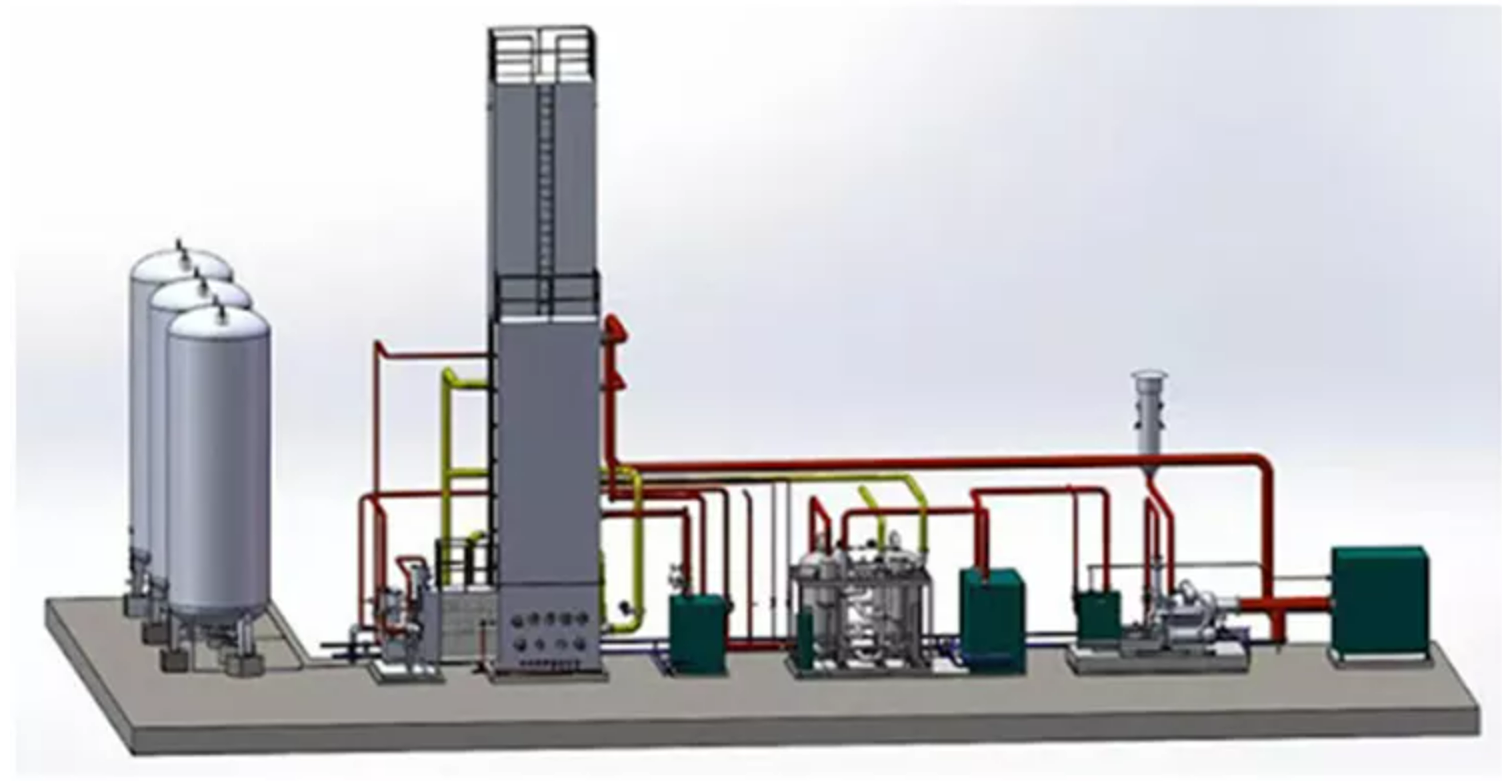

Kunpeng工業用酸素植物空気分離プラント

最新の価格を取得する

お問い合わせを送信

| place of origin : | China |

|---|

もっと

Shenzhen KunPeng Precision Intelligent Technology Co., Ltd

あなたはおそらくそれも好きでしょう

製品説明

Kunpeng Air Separation Unitメーカー

メイン構成

1.エアコンプレッサー:空気は5-7バー(0.5-0.7MPA)の低圧で圧縮されます

2.前冷却システム:空気の温度を12度頃に冷却する

3.清浄機による空気の精製:ツイン分子用ふるいドライヤー

4.エキスパンダーによる空気の極低温冷却:ターボエキスパンダーは、空気の温度を冷却します-165〜170 Deg C

5.空気分離カラムによる酸素と窒素への液体空気の分離

6.液体酸素/窒素は液体貯蔵タンクに保存されています

仕様分類

|

Product Name

|

Cryogenic Air Separation Unit

|

Oxygen Purity

|

≥99.6%

|

|

|

Production

|

50Nm³/h—5000Nm³/h

|

Nitrogen Purity

|

≥99.99%

|

|

|

Brand

|

KunPeng

|

Model

|

KDONAR

|

|

|

Main Part

|

Air compressor system, Pre-cooling System, Air Purification System, Fractionating Column System, Turbo Expander System, Filling System, Instrument and Electric Control System

|

|||

|

Application Field

|

Medical & Industrial & Animal husbandry & Defense

|

|||

プロセスの紹介

|

No

|

MAIN PART

|

FUNCTION

|

||

|

1

|

Air Compression System

|

Air be compressed to 0.5-0.7 Mpa by air compressor, Imported centrifugal air compressor, high efficiency, low consumption, stable and reliable operation

|

||

|

2

|

Pre-cooling System

|

The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated. The original imported screw refrigeration compressor and the air-conditioning unit combined with all imported refrigeration components are equipped with a water separator, manual and imported automatic drains to drain water regularly.

|

||

|

3

|

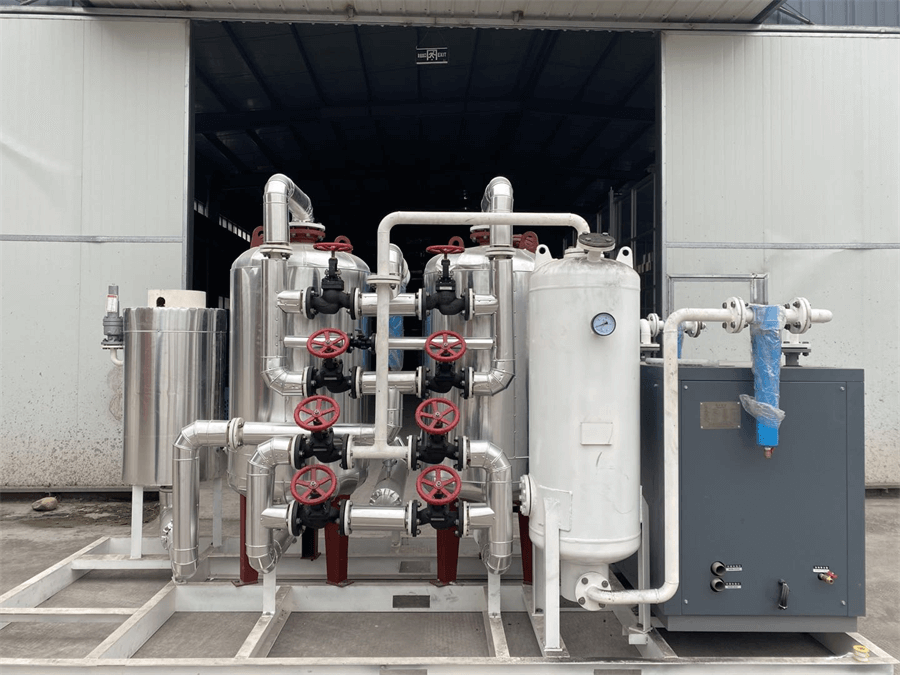

Air Purification System

|

Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier. The purifier adopts a vertical single-layer bed with simple and reliable structure and low resistance loss; built-in filter, blowing off and purifier regeneration at the same time; high-efficiency electric heater ensures complete regeneration of molecular sieve

|

||

|

4

|

Fractionating Column System (Cold Box)

|

The heating, cooling, liquid accumulation and purification of the fractionating tower can be completed in one way, and the operation is simple, quick and easy. Adopt aluminum plate-fin heat exchanger, aluminum convection sieve plate tower, the entire fractionating tower equipment pipeline adopts argon arc welding, the tower body and main pipeline in the cold box are made of high-strength aluminum alloy or stainless steel to increase the strength , Reduce the torsion damage of the pipeline. The equipment brackets, pipes and valve brackets in the cold box shall be made of stainless steel or aluminum alloy. The cold box is insulated with pearl sand and slag wool to ensure that the loss of cold capacity is minimized. The cold box structure guarantees the overall strength and the requirements of anti-seismic and wind resistance, and guarantees the load-bearing capacity of the cold box. When the cold box is running, it is equipped with airtight protection and safety devices. The main equipment in the cold box is equipped with electrostatic grounding. The cold valve and pipeline in the cold box all connections are welded, and flange connections are avoided.

|

||

|

5

|

Turbo Expander System

|

The air expands and cools in the turbo expander and provides the cooling capacity required by the device.The turbo expander adopts gas bearing, which is simple and reliable, easy to operate, and high efficiency. The cold box of the expander is set separately for easy maintenance.

|

||

|

6

|

Heat Exchange System

|

The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

|

||

|

6

|

Filling System

|

Single gas production: Internal compression process ( Cryogenic liquid pump, High pressure vaporizer, Filling manifold).

Multi-gas production: External compression process (Oxygen & nitrogen & argon booster, Filling manifold).

|

||

|

7

|

Instrument and Electric Control System

|

Siemens imported brand, Fully automatic production system, Digital control system

|

||

|

8

|

Others

|

Equipment layout drawing (according to civil engineering design), Process pipe design drawings, Instrument electrical design drawings, etc.

|

||

極低温空気分離植物は広く使用されており、さまざまなアプリケーションシナリオには、流れ、純度、圧力、露点、その他のパラメーターに関する特定の要件があります。ショッピング体験を幸せにするために、需要情報を残してください。プロのエンジニアに連絡し、特定の技術的ソリューションを設計させます。ガス生産装置を参照してください。

このサプライヤーにお問い合わせを送ってください

お問い合わせを送信